Patent Title:

Process for producing tubular ceramic structures of non-circular cross section

Assignee:

Inventors:

Caine M. Finnerty, Benjamin J. Emley

Patent:

Summary Related to Ultrasonic Spray Coating of Fuel Cell Anode:

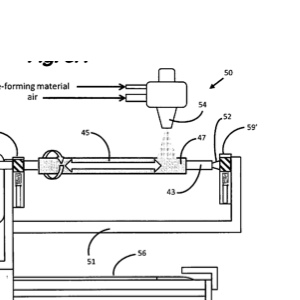

The triangularly shaped mandrel-spindle assembly is rotated about its longitudinal axis at a rate of 125 r.p.m. during the spraying operation. The surface of the rotating mandrel is maintained at a constant distance from the tip of the ultrasonic spray nozzle by the camming modification of the apparatus. The ultrasonic spray nozzle delivers approximately 0.5 ml/sec of anode-forming composition in a slightly bowed-shape spray pattern of microdroplets to the surface of the rotating mandrel. By the time the spray impinges on the surface of the rotating mandrel, sufficient evaporation of the volatile component of the anode-forming composition, namely, its methylethylketone (MEK) slurry-forming component, has taken place so that the sprayed material, now semi-dry, adheres to the mandrel as a substantially uniform coating or layer thereon. Continuous back-and-forth (reciprocal) motion of the traveling support frame of the spraying apparatus results in the increasing accumulation of anode-forming composition on the surface of the mandrel. After a predetermined period of time (or number of spraying cycles), spraying is discontinued, the spindle is removed from the coated mandrel to provide a triangularly shaped mandrel-tubular anode assembly and the latter is weighed to within ±0.01 g from which it is calculated that 5.6 g anode-forming composition, now substantially devoid of its volatile MEK component, has been deposited on the mandrel as a tubular anode structure of generally triangular cross section having the dimensions indicated above.