Patent Title:

Ultrasonic nozzle for coating a medical appliance and method for using an ultrasonic nozzle to coat a medical appliance

Assignee:

Boston Scientific SciMed, Inc.

Inventors:

Gerald Fredrickson

Patent:

Summary of Related to Ultrasonic Spray Coating of Stent:

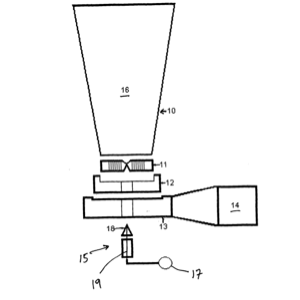

A method for coating a medical appliance includes suspending the medical appliance with a fluidizing gas flow and directing a coating onto an ultrasonic nozzle. The ultrasonic nozzle is directed towards the medical appliance. The method also includes vibrating the ultrasonic nozzle at a rate sufficient to atomize the coating. A device for coating a medical appliance includes a fluidizing gas source adapted to suspend the medical appliance in a suspension area and an ultrasonic nozzle directed at the suspension area and adapted to vibrate. The device also includes a coating source adapted to direct coating onto the ultrasonic nozzle. A medical appliance is provided which has a coating applied by the method.

According to an exemplary method of the present invention, stents are coated using an ultrasonic nozzle to atomize the coating while a fluidizing gas suspends the medical appliances. The fluidizing gas may also deliver the atomized coating from the ultrasonic nozzle to the medical appliances.

By using an ultrasonic coating nozzle, no atomizing pressure is required. This may eliminate the highly focused jet and the consequent shooting of stents at high velocity. There may be sufficient gas flow from the fluidization flow to distribute the atomized coating and keep the stents fluidized.

A method for coating a medical appliance includes suspending the medical appliance with a fluidizing gas flow and directing a coating onto an ultrasonic nozzle. The ultrasonic nozzle is directed towards the medical appliance. The method also includes vibrating the ultrasonic nozzle at a rate sufficient to atomize the coating. The method may also include directing a further gas flow at the ultrasonic nozzle. The further gas flow may transport the atomized coating to the at least one medical appliance. The method may also include directing the fluidizing gas flow at the ultrasonic nozzle. The fluidizing gas flow may transport the atomized coating to at least one medical appliance. The rate of vibration of the ultrasonic nozzle may be between about 48 kilohertz and about 122 kilohertz. The method may also include heating or cooling the fluidizing gas flow. The coating may include a therapeutic agent. The medical appliance may include a stent. The method may be used to coat between 200 and 600 stents. The stent may be a flexible stent. The operation of directing the coating onto the ultrasonic nozzle may include causing a flow of the coating of about 0.5 milliliters per minute. The operation of suspending the medical appliance with a fluidizing gas flow may be performed in a hurricade. The ultrasonic nozzle may be directed to the interior of the hurricade.

A device for coating a medical appliance includes a fluidizing gas source adapted to suspend the medical appliance in a suspension area and an ultrasonic nozzle directed at the suspension area and adapted to vibrate. The device also includes a coating source adapted to direct coating onto the ultrasonic nozzle. The nozzle is adapted to vibrate at a rate sufficient to atomize the coating. The device also may include a further gas source adapted to direct the atomized coating at the suspension area. The device also may include a hurricade enclosing the suspension area.

A medical appliance is provided which has a coating applied by a method which includes suspending the medical appliance with a fluidizing gas flow and directing a coating onto an ultrasonic nozzle. The ultrasonic nozzle is directed towards the medical appliance. The method also includes vibrating the ultrasonic nozzle at a rate sufficient to atomize the coating. The medical appliance may also be made by a method which may also include directing a further gas flow at the ultrasonic nozzle. The further gas flow may transport the atomized coating to the medical appliance. The medical appliance may also be made by a method which may also include directing the fluidizing gas flow at the ultrasonic nozzle. The fluidizing gas flow may transport the atomized coating to the medical appliance.